Brass, an alloy renowned for its distinctive golden hue and versatility, has been a stalwart companion in human technological and artistic endeavors for centuries. To comprehend the intricate nature of this alloy, it’s imperative to dissect its components. Let’s embark on a journey through the alchemical concoction that begets brass, unveiling the synergy of metals that transforms it into a substance of enduring significance.

Copper – The Backbone of Brass

Brass, at its core, is a blend of copper and zinc, each playing a pivotal role in shaping its properties. Copper, the principal constituent, contributes not only to the alloy’s characteristic reddish-brown undertone but also imbues it with remarkable conductivity. In the realm of electrical applications, this attribute renders brass an indispensable material, especially in the creation of Brass Electrical Components.

The synergy between copper and zinc in brass is akin to a harmonious duet, where copper takes the lead in bestowing malleability and thermal conductivity, while zinc introduces its own unique qualities, such as corrosion resistance and hardness.

Zinc – A Balancing Act in Brass

In the alchemical dance that births brass, zinc plays the role of a crucial partner. Through a delicate interplay with copper, zinc introduces strength and durability to the alloy. This amalgamation of metals transforms the soft and malleable copper into a robust material suitable for a myriad of applications.

Zinc, with its distinctive bluish-white appearance, not only enhances the aesthetic appeal of brass but also safeguards it against the ravages of corrosion. This resilience makes brass a preferred choice in environments where exposure to moisture is a constant challenge.

The Alchemy of Brass Electrical Components

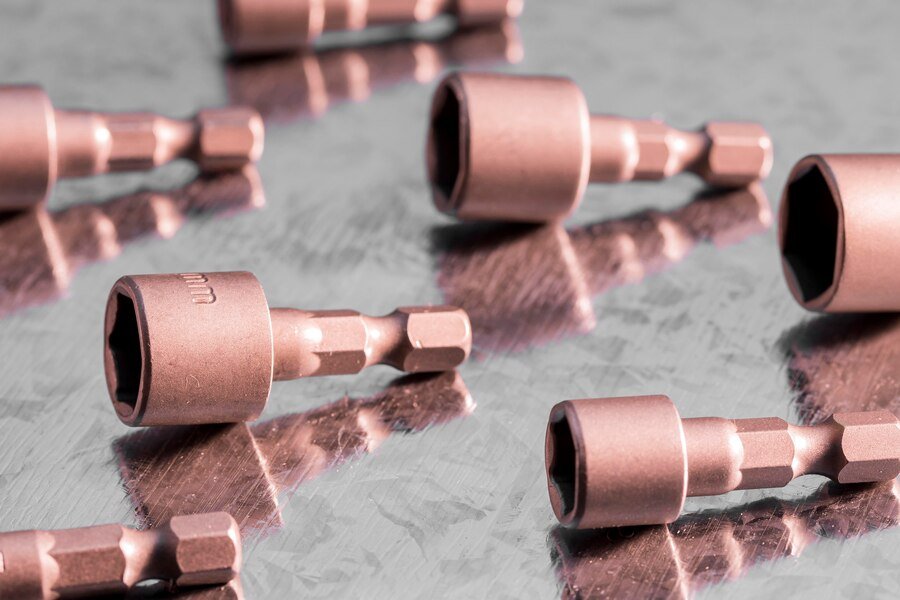

Now, let’s delve into the realm where brass truly shines – brass electrical components. This specialized application leverages the unique combination of copper and zinc to create components that are not only conductive but also possess mechanical strength.

Conductivity Unveiled

At the heart of brass electrical components lies the unparalleled conductivity of copper. The electrons within copper atoms exhibit a remarkable freedom of movement, facilitating the seamless flow of electrical currents. This inherent property makes brass an ideal candidate for electrical connectors, terminals, and various other components within electronic circuits.

Click Here for More Information About Brass Plumbing Fittings.

Strength and Formability

Zinc’s role in brass, apart from enhancing strength, is crucial in shaping the formability of the alloy. The malleability bestowed by zinc allows manufacturers to craft intricate and precise brass electrical components, catering to the diverse needs of modern electrical systems.

The combination of copper’s conductivity and zinc’s formability results in components that not only conduct electricity efficiently but can also be fashioned into complex geometries, ensuring adaptability to the evolving landscape of electronic design.

Corrosion Resistance – A Shield for Longevity

In the realm of electronics, where exposure to the elements is inevitable, the corrosion resistance of brass becomes a defining attribute. Brass Electrical Components stand resilient against the corrosive forces that can degrade the performance of other materials. This durability ensures the longevity and reliability of electronic systems, making brass a cornerstone in the construction of electrical connectors, switches, and terminals.

The Art of Alloying: Precision in Proportions

The alchemical artistry of crafting brass lies not only in the choice of metals but also in the precision of their proportions. The ratio of copper to zinc defines the type and properties of the resulting alloy. Commonly, brass compositions range from 10% to 40% zinc, each formulation catering to specific applications.

Alpha Brass – The Copper Dominance

In the realm of brass, where copper reigns supreme, alpha brass takes the lead. Comprising higher proportions of copper, typically above 65%, it leans towards a redder hue and possesses exceptional ductility. This variant finds its place in the crafting of intricate decorative pieces and instruments where malleability is paramount.

Alpha-Beta Brass – The Balanced Blend

As we delve into the realm of alpha-beta brass, a balanced amalgamation of copper and zinc emerges. With a copper content ranging from 55% to 65%, this variant strikes a harmonious equilibrium between malleability and strength. Brass electrical components often find their origin in this precise composition, combining conductivity with mechanical robustness.

Beta Brass – The Zinc Dominance

On the other end of the spectrum lies beta brass, where zinc takes center stage with compositions exceeding 45%. This variant veers towards a paler hue, reflecting a higher zinc content. While it sacrifices some malleability, it compensates with increased strength, finding applications in the creation of valves, fittings, and components requiring heightened durability.

Forging Ahead: Innovations in Brass Applications

As technology advances and industries evolve, the application of brass continues to diversify, pushing the boundaries of what this alloy can achieve. The world of brass electrical components is no exception, witnessing a constant influx of innovations.

Miniaturization for Microelectronics

In the age of miniaturization, the demand for smaller, yet highly efficient, electronic components has surged. Brass, with its combination of conductivity and formability, has become a linchpin in the development of microelectronic devices. Connectors, switches, and terminals, meticulously crafted from brass, enable the seamless functioning of devices that fit in the palm of our hands.

High-Performance Connectors for Aerospace

In aerospace applications, where reliability is non-negotiable, brass electrical components find a niche as high-performance connectors. The alloy’s corrosion resistance and electrical conductivity make it an ideal candidate for ensuring uninterrupted communication and power supply in the challenging environment of the skies.

Renewable Energy: Brass in Solar Connectors

As the world pivots towards sustainable energy sources, brass has found a new role in the realm of renewable energy. Solar connectors, vital components in harnessing solar power, benefit from brass’s corrosion resistance and electrical conductivity. This application not only underscores the adaptability of brass but also its contribution to shaping a greener future.

Conclusion: Brass – An Ever-Evolving Alloy

In the intricate tapestry of materials that shape our technological landscape, brass stands as a testament to the alchemical ingenuity of the past and the adaptability required for the future. From the nuanced interplay of copper and zinc to the diverse applications in brass electrical components, this alloy continues to forge ahead, embracing innovation while honoring its timeless legacy.

As we navigate the complexities of modern engineering and design, let’s not forget the humble yet extraordinary alloy that has illuminated our lives with its golden glow – brass, an ever-evolving synthesis of elements, a beacon of conductivity, strength, and enduring beauty.

Frequently Asked Questions about Brass and Its Components

1. What is Brass?

Brass is an alloy composed primarily of copper and zinc, known for its distinctive gold-like appearance. The proportion of these metals determines the specific properties of the resulting alloy.

2. What are the Key Components of Brass?

The main components of brass are copper and zinc. Copper provides conductivity and a reddish-brown color, while zinc contributes strength and durability, as well as influencing the alloy’s appearance.

3. What are Brass Electrical Components?

Brass electrical components refer to various parts used in electrical systems that are made from brass. These components leverage the alloy’s conductivity, strength, and corrosion resistance, making them vital in electronic applications.

4. How Does Copper Contribute to Brass?

Copper is the primary component of brass, offering exceptional electrical conductivity and malleability. Its presence defines the alloy’s color and plays a crucial role in the creation of brass electrical components.

5. What Role Does Zinc Play in Brass?

Zinc complements copper in brass, imparting strength, durability, and corrosion resistance. The combination of copper and zinc allows for the versatility of brass in various applications, from decorative pieces to robust connectors.

You May Also Like This