Our Capability

Our Capability

| Processing Material | Brass & Special Copper Alloy Such as BS 2874 CZ 121, UNS 36000, BS 249, S.S. etc… |

| Machining Facility | Bar Turning & Machining on Automatic Lathe Bar CNC Machining and Turning. VMC Machining. Forging + CNC Machining. Casting + CNC Machining. |

| Processing Expertise in: | Turned Engineering Component. Specialized Turned Components Automobile Turned Parts. Brass Sanitary Parts, PPR Fitting, Molding Inserts Brass Wire Terminals & Connectors Lighting & Earthling Protection Parts, Cable Gland Systems. |

| Additional Scope of Work | Complete Assemblies with Plastics and Rubber Parts. |

| Processing Range | 2 mm to 120 mm Diameter |

| Design Aid Software | AutoCAD 3D, 3D Max Studio And Pro-Engineering |

| Documentation | PPAP Level -III |

Our Capability

OUR INFRASTRUCTURE

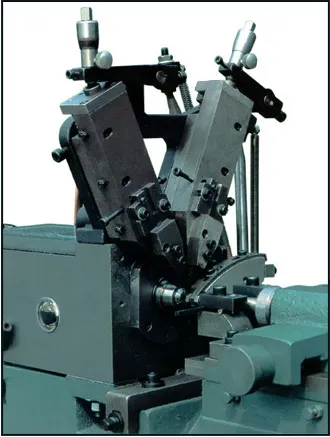

Manufactured objects can be supplied after undergoing machining operations, Single spindle automatic bar turning machines, lathes, and second operation like milling, drilling & threading. Galvanized or coated surface treatments are also available. Instruments like Profile Projector with Geometery Dro, Digital Vernier Calipar, Screw Guage Micrometer, Inner Groove Measuring Instrument,and All Types of Ring and plug Guages according to international thread forms are available.O.K. ENGINEERS COMPONENTS

- High precision turning diameter from 5mm to 50 mm

- Turning length up to 70mm

- High quality Manufacturer of both precision turned parts and automatic machined components, mainly in brass materials.

- Large / medium / small volume production.

FINISHING

Adding value to the supply of machined components and reducing customer input, O.K. Engineers has the in-house expertise to source finishing operation to meet customers exact standard.