Understand the real makeup of stainless steel and how each element plays a vital role in shaping its performance across industries.

When we talk about materials that power the modern world—bridges, machines, even kitchen appliances—Stainless steel is never far from the conversation. But have you ever wondered what gives stainless steel its remarkable strength and resistance to rust? The answer lies in its components. These essential Stainless steel components work together to produce a material that’s both versatile and durable. Many industries depend on carefully engineered stainless steel parts, and it all starts with what’s inside.

The Core Elements That Make Stainless Steel Work

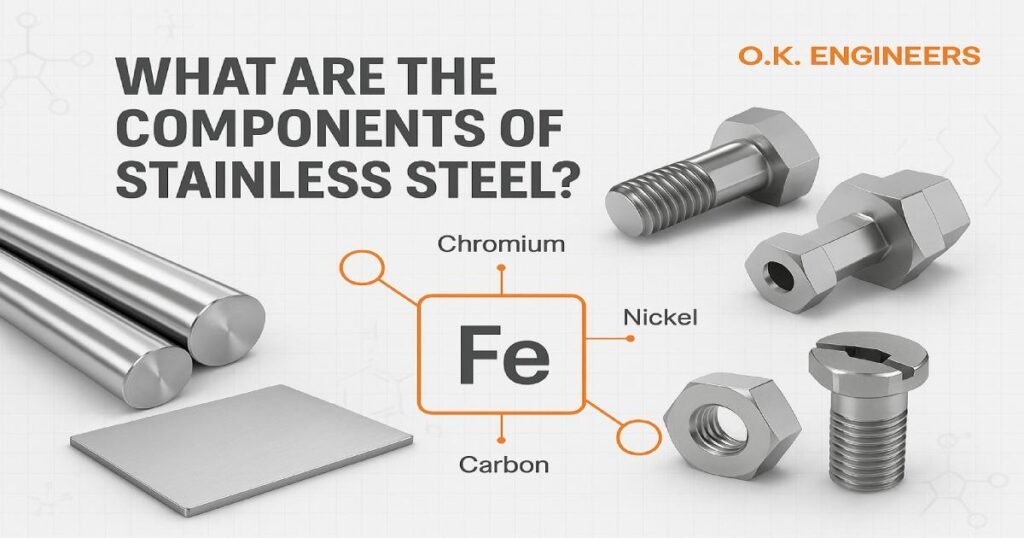

At its foundation, stainless steel is not a single element but an alloy—essentially a custom blend of various metals. Here’s what goes into it:

- Iron (Fe): The primary element, forming the base structure.

- Chromium (Cr): Arguably the star of the mix. With at least 10.5% chromium, stainless steel earns its corrosion-resistant name.

- Nickel (Ni): Adds flexibility and boosts corrosion resistance.

- Carbon (C): Just a small percentage can significantly increase strength and hardness.

- Molybdenum (Mo): Helps fight against pitting, especially in salty or marine environments.

- Other Elements: Small traces of manganese, nitrogen, and silicon also make their way in, each contributing to the alloy’s performance.

These Stainless steel parts are more than just chemical elements—they’re what give the material its identity. And depending on how you mix them, you get different results.

Types of Stainless Steel – And Why the Mix Matters

Not all stainless steels are created equal. Different applications call for different compositions. Here are the four primary categories:

1. Austenitic Stainless Steel

Think kitchen sinks, medical tools, and food processing machines. This type, which includes grades like 304 and 316, contains high levels of chromium and nickel, giving it top-tier corrosion resistance.

2. Ferritic Stainless Steel

Lower in nickel but rich in chromium, this variety is magnetic and often used in automotive exhausts and decorative trim.

3. Martensitic Stainless Steel

Thanks to higher carbon content, this type offers exceptional hardness. You’ll find it in cutlery and surgical tools.

4. Duplex Stainless Steel

A hybrid of austenitic and ferritic properties, duplex stainless offers strength and stress corrosion resistance—perfect for offshore platforms and chemical processing.

What’s interesting is that these different grades aren’t just technical classifications—they directly influence the performance of Stainless steel components in real-world scenarios.

Where You’ll Find Stainless Steel Components in Action

Whether it’s the bridge you cross every day or the food-safe tanks in a factory, stainless steel parts are working silently behind the scenes. Here are some key sectors that rely on them:

- Automobile Manufacturing – Exhaust systems, bumpers, and cladding.

- Construction & Architecture – Roofing, railings, and frameworks.

- Medical Field – Surgical instruments and implants.

- Food Industry – Machinery, utensils, and containers.

- Energy & Marine – Pipelines, tankers, and offshore equipment.

In each of these sectors, the choice of stainless steel isn’t random—it’s based on how its components react under stress, temperature, and exposure.

Why Knowing the Composition Really Matters

If you’re in procurement, engineering, or manufacturing, a deep understanding of Stainless steel parts can prevent costly mistakes. The wrong composition could lead to early failure, especially in harsh environments. Conversely, the right grade improves product life, reduces maintenance, and ensures safety.

At Ok Engineers, we believe informed decisions lead to better results. Our team is dedicated to helping clients choose and manufacture the right stainless steel components that match their needs not just on paper, but in practice.

FAQs

1. What are the core elements in stainless steel?

Stainless steel typically includes iron, chromium, and nickel, along with minor elements like molybdenum and carbon. Each component contributes to its strength, rust-resistance, and durability.

2. What are common uses of stainless steel parts?

From fasteners and gears to pipes and tools, stainless steel parts are used across the medical, food, automotive, and construction industries due to their durability and cleanliness.

3. Why is chromium essential in stainless steel?

Chromium forms a protective oxide layer on the surface, preventing rust and corrosion. It’s the element that essentially makes steel “stainless.”

4. Which type of stainless steel is best for marine environments?

316-grade stainless steel, due to its molybdenum content, is ideal for salty or humid environments like coastal regions or marine equipment.

5. Where can I find reliable stainless steel components?

Look for experienced manufacturers like Ok Engineers, who provide high-quality, customized stainless steel components tailored for performance and longevity.

Follow Us On – Facebook, Instagram

You May Also Like: Which Pipe Fitting is Used for Sanitary Pipes , 2025’s Top Brass Lamp Parts Manufacturers